Often, mathematical modeling is considered a luxury in the product development cycle, or even off critical-path. At Beta Innovations we consider modeling to be a valuable tool during product development for:

- evaluating the performance of design concepts,

- validating optimal prototype designs,

- identifying key performance parameters,

- exploring product performance data, and

- reducing the number of physical prototypes that need to be built and tested.

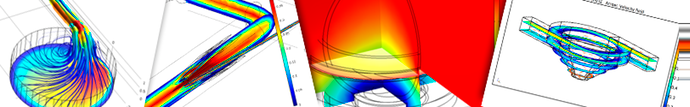

Our modeling expertise is in the areas of:

- fluidics

- heat transfer

- chemical kinetics

- electrokinetic phenomena

These phenomena may be modeled individually or coupled together. COMSOL is a versatile and powerful simulation package that is used to model and couple multiple physics problems.

Examples:

Mathematical modeling has been used to benefit the following development efforts:

- Effects of packaging materials on the storage stability of food products.

- Significance of ion depletion zones in the performance of a novel electrophoretic separation.

- Fluidics evaluation of a dispensing system for manufacturing a lab-on-a-chip device.

- Optimal design and operating parameters of a mixing device by modeling the motion of a free surface on a rocker mechanism.

- Flow profiles in a single-fluid nozzle design.

- Creating balanced flow profiles in a microfluidic electrophoresis device.

- Impact of design variations on the flow patterns of a miniaturized immunoblot assay

- Thermal profiles around heaters in an incubator system.

- Current densities around charged, magnetic particles

- Sample injector design in a flow cytometer-type application